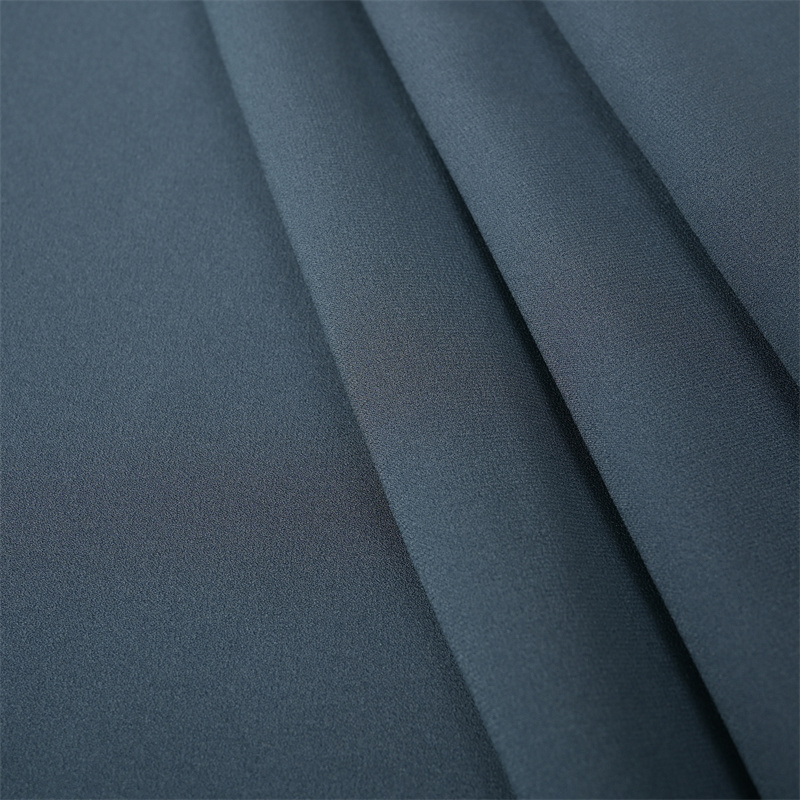

ACETATE POLY ANTI-STATIC,ANTI-ULTRAVIOLET SKIN PROTECTION FABRIC FOR DRESS AC9218

Are you also looking for one?

This item With the new dyeing process, the surface of the fabric is silky, the luster is as soft as the real silk, the drape feeling, the wearability, the protection is beyond the real silk, and has excellent moisture absorption, moisture release, comfortable wearing, is the real breathing face material, the wrinkle resistance is good, easy to manage, at the same time has the natural anti-static, anti-ultraviolet skin protection function.

The structure of acetate fiber longitudinal fiber surface is smooth and uniform, with obvious grooves; As can be seen from its cross-sectional shape, the fiber has no skin-core structure, which is alfalfa leaf-shaped, with smooth periphery and few shallow serrations.

Properties of acetate fiber chemical properties

1. Alkali resistance

Weak alkaline agent did not damage acetate fiber basically, and the fiber weight loss rate was very small. When it meets strong alkali, especially diacetate fiber, it is easy to deacetylate, resulting in weight loss, strength and modulus decrease. Therefore, the pH value of the solution for treating cellulose acetate should not exceed 7.0. Under standard washing conditions, it has strong chlorine bleaching resistance and can also be dry-cleaned with tetrachloroethylene.

2. Resistance to organic solvents

Cellulose acetate is completely soluble in acetone, DMF and glacial acetic acid, but insoluble in ethanol and tetrachloroethylene. According to these characteristics, acetone can be used as the spinning solvent of acetate fiber, and tetrachloroethylene can be used to dry clean acetate fiber fabric.

3. Acid resistance

Acetic acid fiber has good acid stability, and common sulfuric acid, hydrochloric acid and nitric acid will not affect the strength, luster and elongation of the fiber within a certain concentration range. But can be dissolved in concentrated sulfuric acid, concentrated hydrochloric acid and concentrated nitric acid.

4. Colorability

Although cellulose acetate is derived from cellulose, during the esterification process, a large part of polar hydroxyl groups on the glucose ring of cellulose are replaced by acetyl groups. Therefore, dyes commonly used in cellulose fiber dyeing have almost no affinity for cellulose acetate and are difficult to dye. The most suitable dyes for acetate fiber are disperse dyes with low molecular weight and similar dyeing rate.

The acetate fiber or fabric dyed with disperse dyes has bright color, good leveling effect, high dye exhaustion rate, high color fastness and complete chromatography.

Product Parameter

SAMPLES AND LAB DIP

Sample: A4 size/ hanger sample available

Color: more than 15-20 colors sample available

Lab Dips: 5-7 days

ABOUT PRODUCTION

MOQ: please contact us

Leas Time: 30-40 days after quality and color approval

Packaing: Roll with polybag

TRADE TERMS

Trade Currency: USD, EUR or rmb

Trade Terms: T/T OR LC at sight

Shipping Terms: FOB ningbo/shanghai or CIF port